Entry into Retorted products can sometimes seem expensive and confusing. A topic frequently overlooked is Material Handling. In other words, “How do I handle my product filled containers”?

Large producers often invest in high volume, high speed, multi-million-dollar systems. However, these systems don’t fit the price model of an entry level or growing shelf-stable food producer, and far exceed the capacity and throughput requirements that are necessary.

STOCK offers four levels of Entry Level Material Handling Systems. They provide varying levels of semi-automatic and automatic operation, at price points that help newer Food Producers manage costs as they grow their business.

Our Level 1 Material Handling System provides a floor level surface mounted hydraulic scissor jack connected to a frame that provides capability to raise and lower the elevation of the basket bottom. This operator-controlled movement sets the top of the bottom plate at an ergonomic level allowing the operator to load or unload each layer of containers. A powered conveyor is provided to assist loading but is not designed to automatically form the container matrix.

The Level 2 Material Handling System offers additional functionality beyond the L1 system. Level 2 automatically forms the container matrix utilizing a pattern former set to the radius of the container and pattern formers can be changed to handle a variety of containers. Although this application does have some automated mechanical movements, the operator will need to provide sequencing through a pushbutton type interface.

Moving up to the Level 3 Material Handling System continues incremental functionality from the above Entry Level Systems with the addition of automatic layer pad placement.

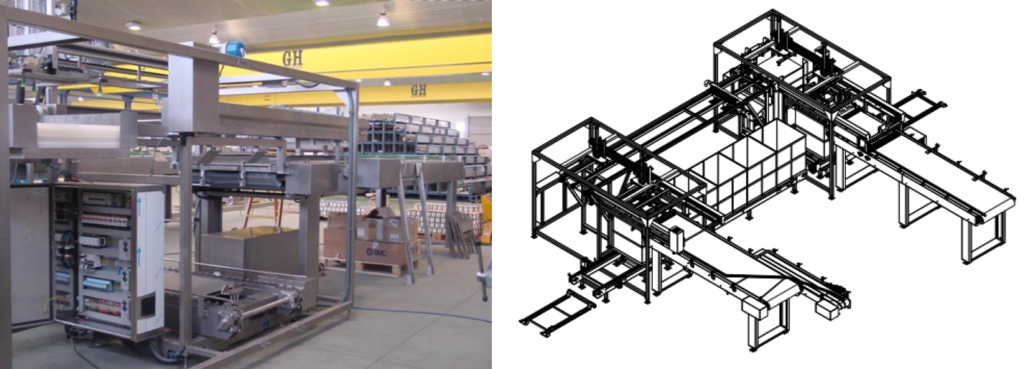

Our Level 4 Material Handling System provides the most inclusive list of features and functionality. This system further eliminates repetitive manual tasks by connecting the loader and unloader modules with a shared platform and conveyance to transport baskets and layer pads. The L4 system is designed to be a complete loader/unloader system managed by a single operator. As an added system upgrade, a Shuttle (X,Y) can be provided to also eliminate the labor-intensive task of transporting, loading, and unloading baskets into and out of the retort(s), providing another level of automation.